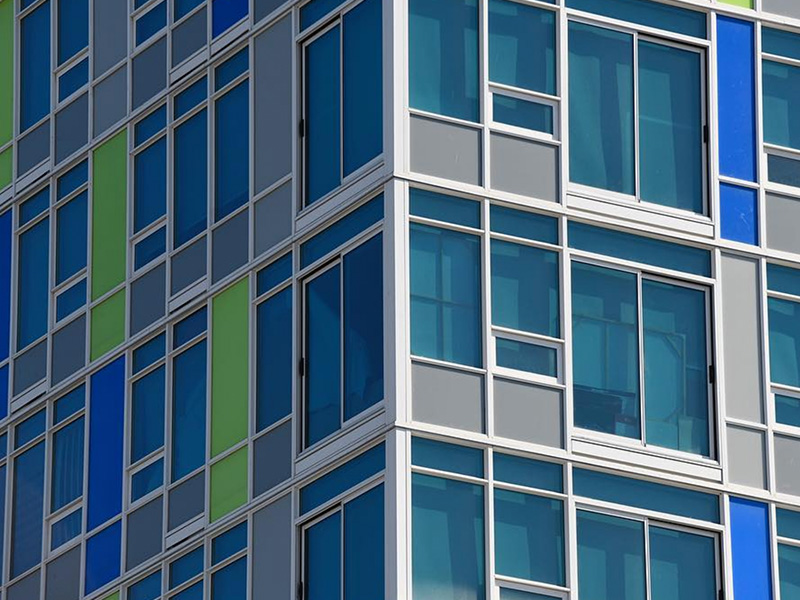

Experience the future of glass aesthetics with OPACI-COAT 300®, a water-based silicone coating that combines elegance with practicality.

Ideal for facade spandrels and decorative panels, this coating offers exceptional performance in color tolerance, UV resistance, and longevity. Transform your architectural visions into reality with a coating that is as durable as it is beautiful.

Better. Stronger. Longer

![]() World Class Strength – Unlike frit, OPACI-COAT 300® doesn’t weaken glass to which it is applied, and offers superior fall-out protection.

World Class Strength – Unlike frit, OPACI-COAT 300® doesn’t weaken glass to which it is applied, and offers superior fall-out protection.

![]() Clean Chemistry – OPACI-COAT 300® is a silicone, water-based elastomeric coating that requires no organic solvents or heavy metals; and it’s lead-free. Our silicone product is healthier for people and the planet.

Clean Chemistry – OPACI-COAT 300® is a silicone, water-based elastomeric coating that requires no organic solvents or heavy metals; and it’s lead-free. Our silicone product is healthier for people and the planet.

![]() Superior Color Matching – OPACI-COAT 300® is unrivaled in the industry for color matching to an undetectable tolerance of 0.20dE, including metallics.

Superior Color Matching – OPACI-COAT 300® is unrivaled in the industry for color matching to an undetectable tolerance of 0.20dE, including metallics.

![]() Protect Your Investment – ICD Approved Factory Fabricators are professionally trained and available world-wide. Expect impeccable results and consistency in application.

Protect Your Investment – ICD Approved Factory Fabricators are professionally trained and available world-wide. Expect impeccable results and consistency in application.

![]() No wastage – OPACI-COAT 300 reduces the variables of failure from frit breakage and color inaccuracy, increasing cost-efficiency and on-time delivery.

No wastage – OPACI-COAT 300 reduces the variables of failure from frit breakage and color inaccuracy, increasing cost-efficiency and on-time delivery.

Better than ceramic frit across the board

Applications

Facade Spandrel

Elevate exterior aesthetics with a high-performance glass coating

Interior Wall Cladding

Transform your interiors with elegant and durable glass coatings

Solar Panels

Upgrade spaces with stylish and resilient backsplash glass coatings

OPACI-COAT-300® is ICD’s flagship water-based silicone glass coating engineered specifically for spandrel glass, interior wall cladding, and other opaque architectural glass applications. As a 1K (single-component) silicone elastomer system, it provides a durable, flexible, and chemically resistant opaque film that adheres to virtually all architectural glass types. The system is known for its excellent color uniformity, long-term performance, and ultra-low VOC formulation, making it suitable for high-performance commercial and institutional projects where sustainability, consistency, and lifecycle durability are critical.

The coating offers an unlimited opaque color palette with precise batch-to-batch matching, supported by ICD’s controlled manufacturing and certification programs. Because the coating is applied by trained/approved fabricators, projects benefit from repeatable application quality, controlled film build, and reliable visual results across large façades. Its adhesion and flexibility characteristics help maintain coating integrity under thermal cycling, while its 100% opaque formulation makes it a widely adopted alternative to ceramic frit, often providing improved thermal stress mitigation and aesthetic control.

Download product details

OPACI-COAT-300® integrates into complex façade systems—including ventilated façades, 2-sided, and 4-sided structural glazing, where it is approved for use on spandrel glass. The material is lead-free, water-based, BABA-compliant, and manufactured in the United States. Extensive documentation exists for specifications, handling, application, compatible materials, LEED/HPD compliance, color guides, test data, and safety information. Collectively, these properties position OPACI-COAT-300® as a highly adaptable, sustainable, and performance-reliable solution for architects, glaziers, and fabricators seeking a proven opaque glass coating system.

A World of Colors

Color matters. Whether you are looking for colors to harmonize with your building, create a pop of color for contrast, or both, we’ll help you achieve your color goals.

Due to increased demand for spandrel and wall-cladding color options, our current library contains over 26,000 colors. Choose from 16 standard colors, or explore our selection of 50 curated colors. If you’re in search for the “perfect” color, contact ICD and request our Custom Color Matching Service.

ICD is known for exceptional color matching, including delivering vibrant reds and yellows. While some have tried to recreate our proprietary color processes, choosing ICD Colors mean guaranteed performance and beauty.

ICD Color challenge

FAQ

Your Title Goes Here

Your content goes here. Edit or remove this text inline or in the module Content settings. You can also style every aspect of this content in the module Design settings and even apply custom CSS to this text in the module Advanced settings.

What Is OPACI-COAT-300®

A water-based silicone spandrel and interior wall cladding glass coating for fully opaque, cavity-backed applications. It offers a wide range of colors, does not weaken the glass substrate, and provides fallout resistance when applied appropriately.

How can samples of OPACI-COAT-300®

OPACI-COAT-300® coated glass samples can be requested through the ICD website, where you can specify the type of glass and the desired color. This allows for a physical evaluation to ensure the color and finish meet the project’s specifications. Contact ICD with any sample questions.

Who can purchase OPACI-COAT-300®

Approved Factory Fabricators (AFF’s) are the glass processing companies who are certified to make beautiful backpainted glass products like spandrel and wall cladding with OPACI-COAT-300® water-based silicone glass coating. AFF’s stretch across the globe creating a large sourcing network for anyone looking to purchase OPACI-COAT-300® coated glass. Each AFF is certified yearly to ensure year-over-year consistency in material handling, application, and their ability to produce excellent silicone coated glass. AFF’s are the only businesses allowed to purchase and apply OPACI-COAT-300®. Contact ICD if interested in becoming an AFF, or to learn about the AFF’s located in your region.

What are the color options for OPACI-COAT 300®

OPACI-COAT-300® comes in 16 standard industry colors and offers an extensive range of custom colors, matching over 26,000 shades from major color systems like Pantone, RAL, Sherwin Williams, and Benjamin Moore. This flexibility ensures that virtually any desired shade can be achieved for specific project requirements. Interested in a coated glass sample? Contact ICD.

Where can OPACI-COAT 300® coated glass be installed?

OPACI-COAT-300® was developed and is tested to withstand the temperature and humidity extremes of spandrel glass in facade building envelopes.

Which glass surfaces can OPACI-COAT-300® be applied to?

On monolithic glass, OPACI-COAT-300® is applied to surface 2. On an IGU, OPACI-COAT-300® can be applied to surface 2 or surface 4. Surface 2 is used for a more bold up-front color look, but will need to be edge deleted for the primary seal to adhere directly to the glass. Surface 4 is used for a look of depth and is the recommended surface when using facade visual harmonization suggested colors. See FAQ about low-e coatings if low-e coatings are present.

Can OPACI-COAT 300® be used with low-emissivity (low-e)

OPACI-COAT-300® is compatible to be applied on top of some hardcoat (pyrolytic) low-e coatings. Contact ICD for compatibility test results. OPACI-COAT-300® cannot be applied on top of softcoat low-e coatings and cannot share an IGU airspace with softcoat low-e coatings. If a softcoat low-e coating is being utilized on surface 2 or 3 of an IGU, OPACI-COAT-300® needs to be applied on surface 4.

Can OPACI-COAT 300® can be used on diffrent types of glass?

Yes, it is compatible with all types of glass, including annealed, heat-strengthened, and tempered glass. The product enhances the glass’s integrity. In the event of 6mm tempered glass breakage, if OPACI-COAT-300® was applied at 13 mil WFT it will provide fallout resistance by holding 6mm tempered glass broken pieces in place until it can be replaced.

Is OPACI-COAT 300® environmentally friendly?

OPACI-COAT-300® is lead-free, ultra-low in VOCs, and does not contain heavy metals, making it a greener choice for glass coating applications. It also aligns with the Build America, Buy America (BABA) Act, confirming its manufacture in the United States under stringent environmental and labor standards.

How does OPACI-COAT 300® compare with frit?

OPACI-COAT-300® offers several advantages over ceramic frit, including better environmental profiles, a broader color palette, and the ability to strengthen glass rather than weaken it. It also has a unique property of fallout resistance, which keeps 6mm tempered glass pieces from falling out of their frame in case of breakage.

Product data & safety

Product Safety Sheet – Download Here

Product Safety Sheet – Download Here

Safety Data Sheet – Download Here

Safety Data Sheet – Download Here

Sustainability & Transparency

OPACI-COAT® Health Product Declaration® v2.3 100 PPM

OPACI-COAT-300® Health Product Declaration® v2.3 100 PPM

OPACI-COAT 300® U.S. Green Building Council (USGBC) LEED v4 Points

OPACI-COAT-300® in the Mindful Materials Library

In accordance with the requirements set forth by the Build America, Buy America (BABA) Act, included within the Infrastructure Investment and Jobs Act (IIJA), we hereby certify and affirm our product, listed below, is manufactured in the United States and meets the criteria defined under the Build America, Buy America (BABA) Act:

OPACI-COAT-300® water-based silicone glass coating is a polymer-based product entirely manufactured in Washington state and the production process is carried out by a skilled American workforce, adhering strictly to federal, state, and local laws, including labor and environmental standards.